Abstract

Margarine pastry ga-abụ plastik ma kwụ ọtọ.Enwere ike ịhazi usoro teknụzụ nke imepụta margarine achịcha achịcha dị mfe site na tubularchiller (onye na-ekpo ọkụ na-ekpo ọkụ n'elu tubular).N'oge a na-arụ ọrụ nke ọma nke mmanụ, jụrụ oyi na-enwe mmetụta dị ukwuu na kristal nke margarine pastry.Margarine dị iche iche chọrọ usoro dị iche iche na ọnọdụ okpomọkụ.

Margarine pastry ga-abụ plastik ma kwụ ọtọ.Enwere ike ịhazi usoro teknụzụ nke imepụta margarine achịcha achịcha dị mfe site na tubularchiller (onye na-ekpo ọkụ na-ekpo ọkụ n'elu tubular).N'oge a na-arụ ọrụ nke ọma nke mmanụ, jụrụ oyi na-enwe mmetụta dị ukwuu na kristal nke margarine pastry.Margarine dị iche iche chọrọ usoro dị iche iche na ọnọdụ okpomọkụ.

Isi okwu : pastry margarine;drum oyi;tubular chiller, ihe na-ekpo ọkụ n'elu kpụkọrọ akpụkọ, mmepụta margarine.

Nkà na ụzụ mmeghe nke tubular chiller

Ọ bụ ezie na ngwaahịa margarine flaky na-emepụta kemgbe ọtụtụ afọ, ndị mmadụ na-agbalị ịchọta ụzọ kachasị mma maka ọnọdụ usoro, karịsịa na crystallization nke usoro ngwaahịa dị iche iche n'okpuru ọnọdụ nhazi dị iche iche.Tupu e mepụta ihe na-ekpo ọkụ na-ekpo ọkụ, ma ọ bụ igwe na-emenyụ tube, a na-eji igwe na-emenyụ ọkụ na igwakorita eme ihe niile margarine.N'ihi na nke tube quenching nhazi igwe nwere ọtụtụ uru ma e jiri ya tụnyere ndị ọzọ nhazi ígwè ọrụ, otú ugbu a, margarine na-emepụta na-eji ya mmepụta nke flaky pastry margarine, akwụkwọ a na quenching tube nhazi igwe na-emepụta flaky pastry margarine usoro ime ụfọdụ mmeghe.

Ihe ndị bụ isi nke margarine flaky bụ plasticity na nkwụsi ike ya.Mgbe a na-apịa margarine ma na-atụgharị ugboro ugboro, ọkwa ndị ahụ ga-anọgide na-agbajighị na mgwakota agwa, ya mere plasticity dị mkpa;Nkwụsi ike dịkwa mkpa.Ọ bụrụ na margarine ahụ esighi ike nke ọma ka ọ dị nro ma ọ bụ mmanụ na-agbaze, ma tinye ya n'ime mgwakota agwa, a ga-ebelata oke mmanụ n'etiti ntụ ọka ntụ ọka.

Ọdịdị nke igwe na-emenyụ ọkụ rotary drum dị mfe, ọ bụ naanị na ọ dị mkpa ka ịhazigharị paramita ole na ole na mmepụta nwere ike ịmepụta ngwaahịa margarine dị nro.Margarine pastry pastry nke na-emepụta nke igwe na-eme ka drum quench na-emepụta nwere ezigbo plasticity, ọ dịghị mfe ịbanye mmanụ, ọ na-akwụsikwa ike na oke okpomọkụ.Igwe na-ekpo ọkụ Tube karịa igwe na-eme ka ọ bụrụ na arụ ọrụ emeela ọganihu dị ukwuu, nke a na-egosipụta na:

(1) Na ngwaahịa nhazi ọkpọkọ a na-emechi emechi, ezigbo akara, ọnọdụ ịdị ọcha ga-akawanye mma;

(2) Nghọta nke ọrụ nrụgide dị elu, nke dị mkpa karịsịa maka mmepụta nke margarine crisp;

(3) Mgbanwe dị mma, nwere ike ịgbanwe ọsọ ọsọ, nrụgide, ike oyi na ọnọdụ nhazi ndị ọzọ.

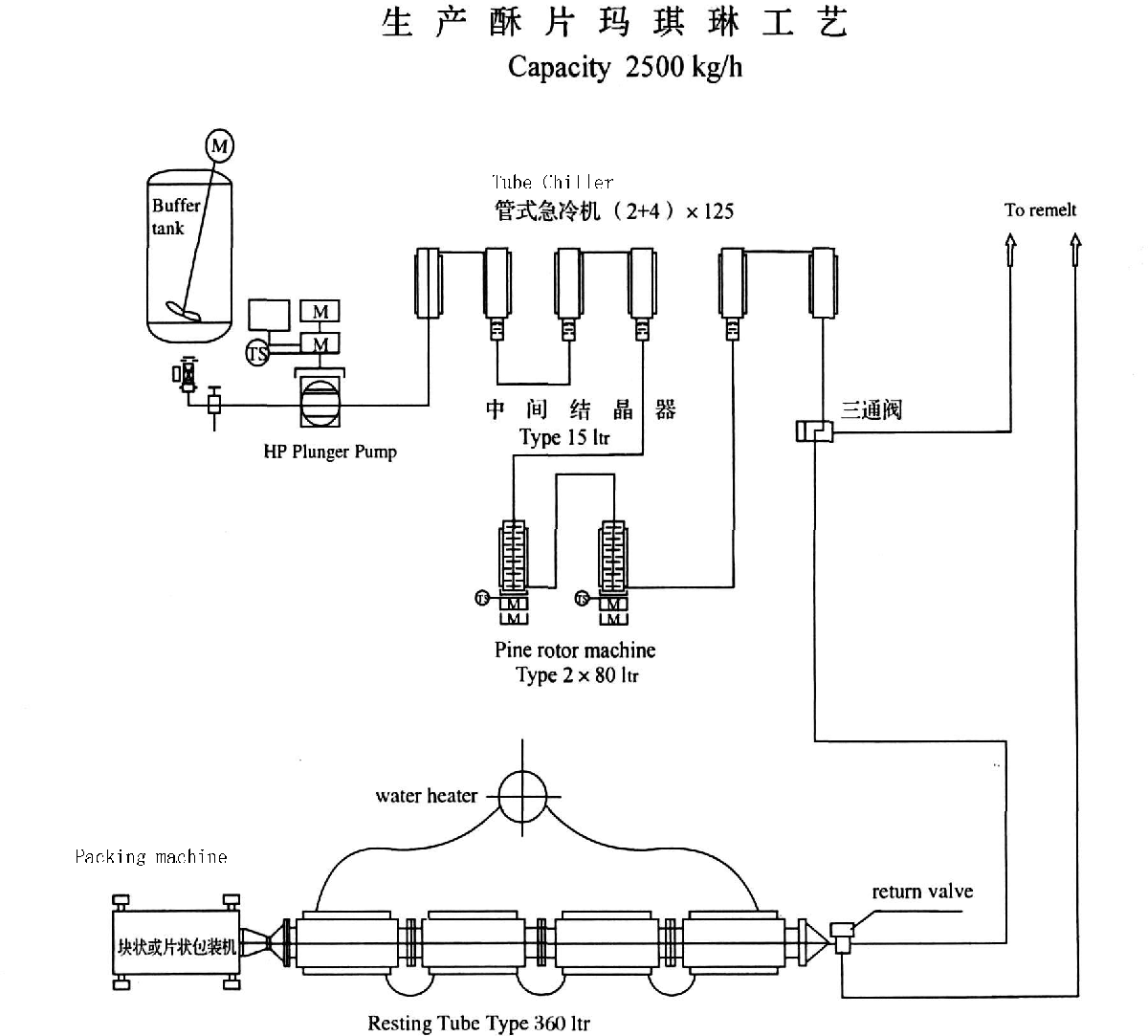

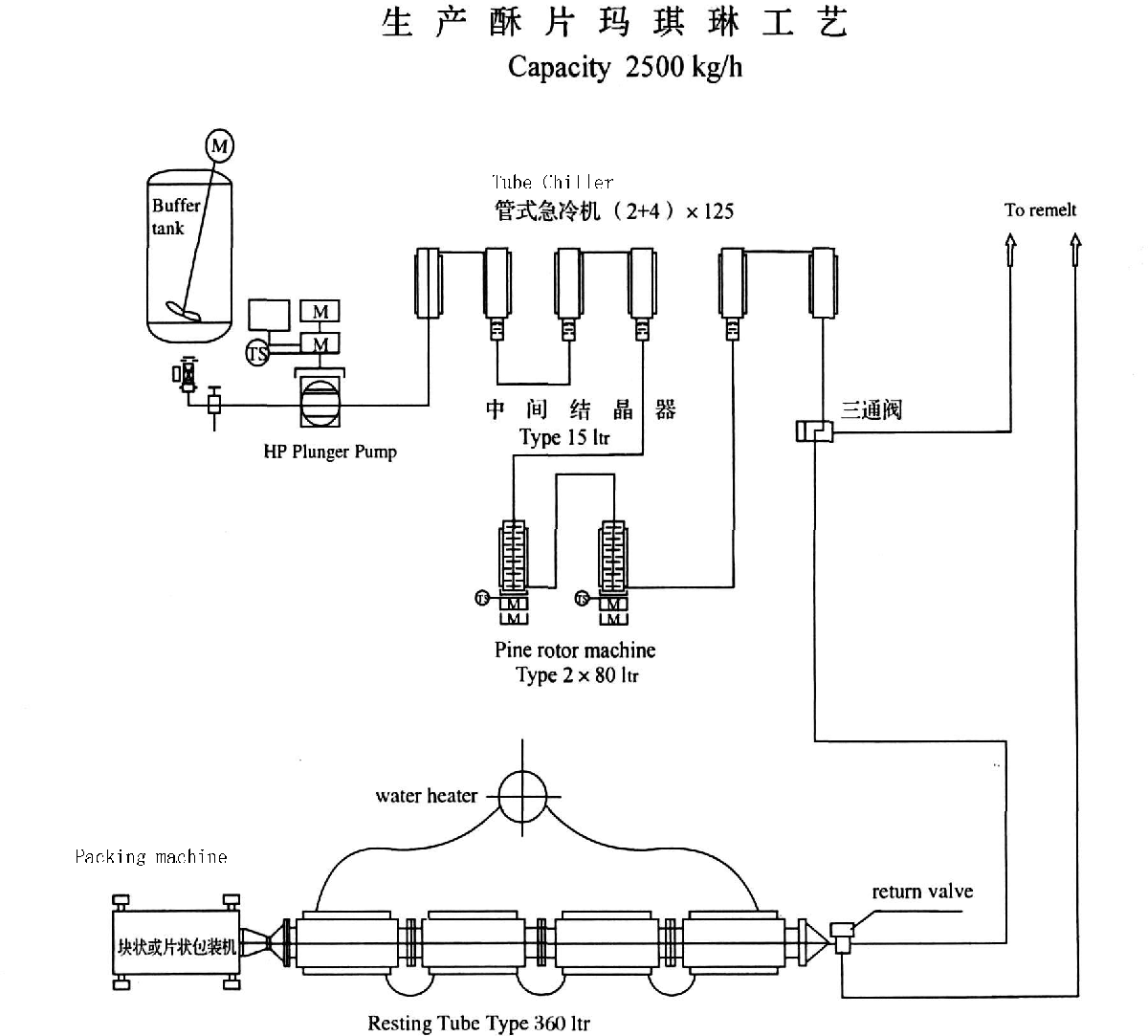

Usoro nnochite anya maka imepụta margarine pastry flaky site na igwe quenching tube bụ nke a:

Mgbapu plunger dị elu ※ Nnukwu nrụgide tubular scraped elu okpomọkụ Exchanger (Unit A) ※ Intermediate crystallizer set ※ Na-emegharị pine rotor igwe (Unit B) ※ Nnukwu ikike izu ike ※ mkpọkọ / mgbochi.

Ọrụ nke kristal etiti dị n'etiti ya na nke ihe na-akpali akpali.Ọ dị na ọkpọkọ quench nke igwe na-edozi ma na-emegharị ya ka ọ na-atụgharị site na mpempe ihe nkedo nke igwe nhazi.

Ọ na-adaba adaba iji dozie usoro nhazi nke ngwaahịa ahụ iji mepụta margarine pastry pastry na igwe quenching tube.Enwere ike nweta ebumnuche nke ịhazigharị usoro ahụ site n'ịgbanwe ọnọdụ njikọ nke ọkpọkọ njikọ n'etiti quenching pipe group (unit A) na kneading unit (unit B), nke dị mfe ịrụ ọrụ.Dị ka ihe atụ, a pụrụ idobe ihe na-akpali akpali igwakorita unit (unit B) n'etiti quench ọkpọkọ nke unit A, na-eso eruba nke A 1 ※ A 2 ※ B1 ※ B2 ※ A 3 ※ A 4, ma ọ bụ na-agbanwe na eruba. nke A1※A 2※A 3※A 4※B1※B2.Naanị ịgbanwe usoro nhazi nwere ike melite ogo ngwaahịa.N'ime usoro dị n'elu, usoro nke itinye unit B n'etiti quench tube nke unit A dị mma karịsịa maka mmepụta mmanụ ihe oriri na-adabere na mmanụ nkwụ, bụ nke egosipụtara ọtụtụ ugboro na mmepụta ihe.Ma mgbe isi ihe nke ngwaahịa ahụ bụ ehi, enwere ike nweta nsonaazụ ka mma site na itinye unit B mgbe nkeji A gachara.

A na-ekpebi ike igwakorita site na nhazi nke ngwaahịa ahụ, dịka ọmụmaatụ, a ga-eji ike ikpokọta dịtụ ukwuu maka ịmepụta mmanụ na-eji nwayọọ nwayọọ kristal.Na ngwa ngwa jụrụ pipụ mmepụta usoro, na igwakorita mmetụta bụ ikike nke etiti otu na ikike nke crystallizer na iti na igwakorita unit (B) nchikota nke ikike nke unit, otú mgbe mgbanwe na ngwaahịa usoro, mkpa. ka ịgbanwe ikike nke igwakorita usoro, ma site B unit ikike abawanye ma ọ bụ ibelata, nwere ike na-amụba ma ọ bụ ibelata na n'etiti ebu ikike, Ọ pụrụ ọbụna mere site na-agbakwụnye na subtracting n'otu oge ahụ, nnọọ mgbanwe.

A na-ekpebi ike igwakorita site na nhazi nke ngwaahịa ahụ, dịka ọmụmaatụ, a ga-eji ike ikpokọta dịtụ ukwuu maka ịmepụta mmanụ na-eji nwayọọ nwayọọ kristal.Na ngwa ngwa jụrụ pipụ mmepụta usoro, na igwakorita mmetụta bụ ikike nke etiti otu na ikike nke crystallizer na iti na igwakorita unit (B) nchikota nke ikike nke unit, otú mgbe mgbanwe na ngwaahịa usoro, mkpa. ka ịgbanwe ikike nke igwakorita usoro, ma site B unit ikike abawanye ma ọ bụ ibelata, nwere ike na-amụba ma ọ bụ ibelata na n'etiti ebu ikike, Ọ pụrụ ọbụna mere site na-agbakwụnye na subtracting n'otu oge ahụ, nnọọ mgbanwe.

Oge nzipu: Dec-30-2021