Ahịrị Mmepụta ihendori custard

Ahịrị Mmepụta ihendori custard

Ahịrị Mmepụta ihendori custard

Vidiyo Mmepụta:https://www.youtube.com/watch?v=AkAcycJx0pI

Aahịrị mmepụta ihendori custardỌ gụnyere usoro akpaghị aka na nke ọkara akpaaka iji mepụta ofe custard nke ọma, n'otu n'otu, na n'ụzọ dị ọcha. N'okpuru ebe a bụ nkọwa zuru ezu nke usoro ndị a na-ahụkarị n'usoro mmepụta ofe custard:

1. Njikwa na Nkwadebe Ihe E Ji Mee Ya

- Nnabata na Nchekwa Mmiri ara ehi

- A na-enweta mmiri ara ehi a na-anaghị esi esi, a na-anwale ya ma ọ dị mma, ma debe ya n'ime silos dị na friji.

- Nhọrọ ọzọ: ntụ mmiri ara ehi e megharịrị emegharị + mmiri (maka ndụ nchekwa ogologo oge).

- Njikwa Shuga na Ihe Na-eme Ka Ọ Dị Ụtọ

- A na-atụ shuga, sirop ọka, ma ọ bụ ihe ụtọ ndị ọzọ a na-eji atụ ma gbazee.

- Nhazi ntụ ntụ àkwá na àkwá

- A na-agwakọta àkwá mmiri mmiri (nke e tinyere pasteurized) ma ọ bụ ntụ àkwá na mmiri.

- Starch na ihe ndị na-eme ka ihe sie ike

- A na-agwakọta ntụ ọka, starch a gbanwere agbanwe, ma ọ bụ ihe ndị na-eme ka ihe sie ike (dịka ọmụmaatụ, carrageenan) tupu oge eruo iji gbochie nchikọta.

- Ihe na-atọ ụtọ na ihe mgbakwunye

- A na-akwadebe vanilla, caramel, ma ọ bụ ihe ndị ọzọ na-atọ ụtọ, tinyere ihe nchekwa (ọ bụrụ na ọ dị mkpa).

2. Ịgwakọta na Ịgwakọta

- Ngwakọta ma ọ bụ ngwakọta na-aga n'ihu

- A na-ejikọta ihe ndị e ji mee ihe naigwekota ihe dị eluma ọ bụtankị ngwakọta mbụn'okpuru okpomọkụ a na-achịkwa (iji zere ịka nká tupu oge eruo).

- Enwere ike iji Homogenization mee ihe maka udidi dị nro.

3. Isi nri na ime ka ọ dị ọcha

- Nri Na-aga n'ihu (Ihe Mgbanwe Okpomọkụ Elu Ala A Kpụchapụrụ Akpọcha)

- A na-ekpo ọkụ ngwakọta ahụ ka ọ dị ọkụ75–85°C (167–185°F)iji mee ka gelatinization nke starch rụọ ọrụ ma mee ka ofe ahụ sie ike.

- Pasteurization (HTST ma ọ bụ Ogbe)

- Obere oge okpomọkụ dị elu (HTST) na72°C (161°F) maka sekọnd 15-20ma ọ bụ pasteurization nke otu ngwugwu iji hụ na nchekwa nje bacteria dị.

- Oge oyi

- Jụụ ngwa ngwa iji4–10°C (39–50°F)iji kwụsị isi nri ọzọ ma nọgide na-enwe ọdịdị.

4. Nhazi otu (Nhọrọ)

- Homogenizer nrụgide dị elu

- A na-eji ya eme ihe maka udidi dị nro nke ukwuu (na-egbochi ire ụtọ).

5. Njupụta na Nkwakọ ngwaahịa

- Igwe Na-ejuputa Akpaka

- Njuputa akpa(maka ahịa) ma ọ bụnjupụta buru ibu(maka ọrụ nri).

- Ihe njupụta Aseptic(maka ogologo oge nchekwa) ma ọ bụihe jupụtara ọkụ(maka nchekwa gburugburu).

- Ụdị Nkwakọ ngwaahịa:

- Karama plastik, katọn, akpa, ma ọ bụ ite.

- Enwere ike iji nitrogen chụpụ ihe ọkụkụ iji mee ka oge nchekwa dị ogologo.

6. Ịjụ oyi na Nchekwa

- Ịgba oyi ọkụ (ọ bụrụ na achọrọ)

- Maka ude a na-etinye n'ime friji, jụọ oyi ngwa ngwa4°C (39°F).

- Nchekwa Oyi

- Echekwara na4°C (39°F)maka ude ọhụrụ ma ọ bụ ihe dị mma maka ngwaahịa ndị e tinyere n'ime UHT.

7. Njikwa na Nnwale Ogo

- Nnyocha Viscosity(na-eji viskometers).

- Nlekota pH(ihe mgbaru ọsọ: ~6.0–6.5).

- Nnwale Microbiological(ọnụọgụ efere niile, yist/ebu).

- Nyocha Mmetụta Uche(uto, udidi, agba).

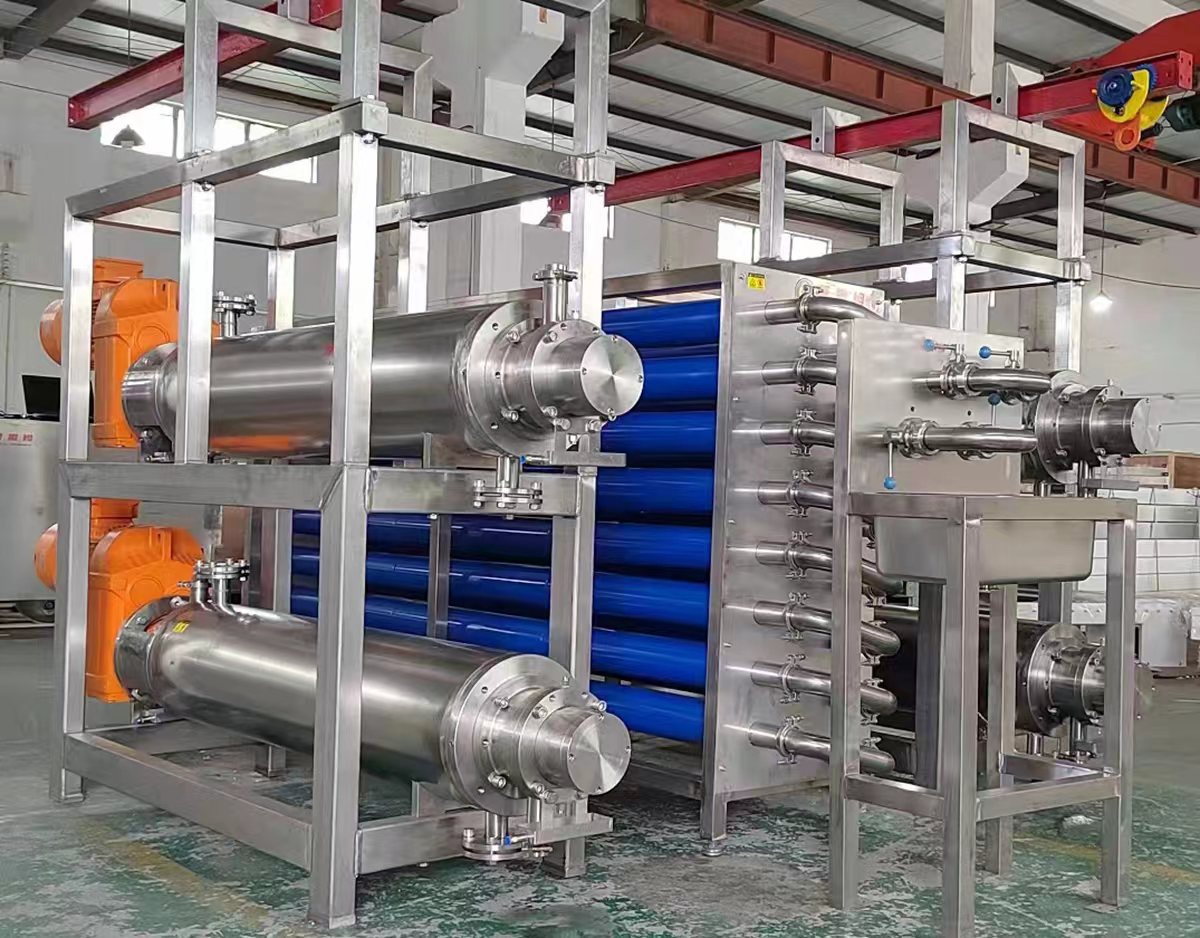

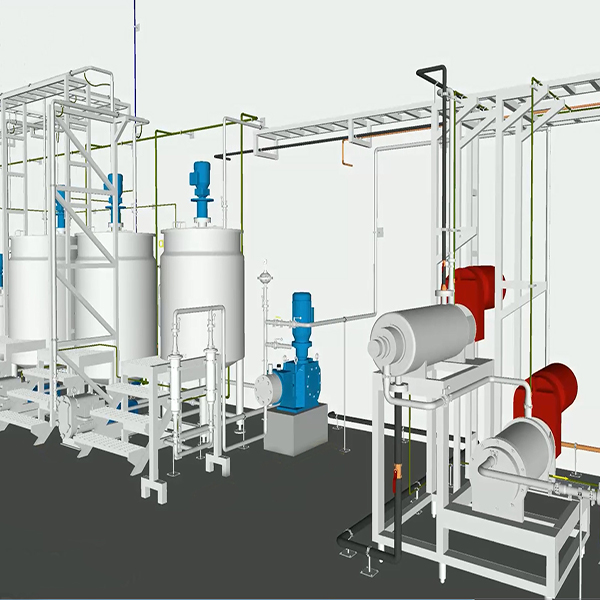

Ngwa dị mkpa na Ahịrị Mmepụta Ofe Custard

- Tankị Nchekwa(maka mmiri ara ehi, ihe ndị e ji mmiri mee).

- Sistemụ Ịtụle na Ịtụle Ọgwụ.

- Ngwakọta Ịcha Elu na Tankị Premix.

- Pasteurizer (HTST ma ọ bụ Batch).

- Ihe Mgbanwe Okpomọkụ Elu A Kpụchapụrụ Akpọcha (maka esi nri).

- Homogenizer (nhọrọ).

- Igwe eji emeju ihe (piston, volumetric, ma ọ bụ aseptic).

- Ọwara oyi.

- Igwe Nkwakọ ngwaahịa (akara, akara).

Ụdị ihendori Kustard Emepụtara

- Kustard e tinyere na friji(oge nchekwa dị mkpirikpi, uto ọhụrụ).

- UHT Custard(oge nchekwa ogologo oge, sterilaiz).

- Ngwakọta Kustard e tinyere ntụ(maka nhazigharị).

Akpaaka na arụmọrụ

- Sistemụ Njikwa PLCmaka njikwa okpomọkụ na ngwakọta ziri ezi.

- Sistemụ CIP (Nhicha-n'Ebe)maka ịdị ọcha.

Ọrụ Ebe

Dee ozi gị ebe a zitere anyị ya